| Issue |

BIO Web Conf.

Volume 68, 2023

44th World Congress of Vine and Wine

|

|

|---|---|---|

| Article Number | 02035 | |

| Number of page(s) | 5 | |

| Section | Oenology | |

| DOI | https://doi.org/10.1051/bioconf/20236802035 | |

| Published online | 22 November 2023 | |

Impact of fermentation-temperature management combined with specific yeast choice on energy savings in white winemaking

1 Department of Agricultural and Environmental Sciences - Production, Landscape, Agroenergy, Università degli Studi di Milano, Via Celoria, 2, 20133 Milan, Italy

2 Department of Biomedical, Surgical and Dental Sciences - One Health Unit, Università degli Studi di Milano, Via Mangiagalli, 25, 20133 Milan, Italy

3 CREA, Council for Agricultural Research and Economics, Research Centre for Viticulture and Enology, Viale XXVIII Aprile 26, 31015 Conegliano, Italy

* Corresponding author: tiziana.nardi@crea.gov.it

Heat removal significantly impacts energy request in the winery and is related to the temperature control of wine tanks during the fermentation process and the wine maturation phase. The aim of this work was twin: first, to determine the heat dissipated from tanks under different temperature fermentation programs, to evaluate the impact of temperature management combined with specific yeast choice on energy saving during industrial-scale (450 hL) white vinification. Second, to explore the applicability of such protocols, and the extent of the potential effects thereof, through a survey. Comparative winemaking tests were carried out by using properly chosen yeasts during fermentation of Glera and Pinot Grigio musts at usual winery temperature (15 or 17-15 °C) and 19 °C, verifying the quality of the resulting wines in term of sensory, chemical and aromatic features. Fermentation required on average 7.0 Wh dm-3 at 19 °C and 10.3 Wh dm-3 must at 15/17-15 °C, reducing energy use by ~32% at the higher temperature, without compromising sensory, chemical, and aromatic profiles of wines. Then, the potential widespread of those effects was investigated through a survey involving several (n>100) wineries: among others, questions about vinification volumes, usual fermentation temperatures and attitude towards energy-saving innovations were asked to winemakers. Our results suggest that wineries can adopt a more sustainable winemaking process with low energy consumption and that this choice may have a relevant impact on white-winemaking energy consumption in the Italian context. Indeed, ~70% of a sample of winemakers representing an overall production of 1.300.000 hL, declared a willingness to increase their usual fermentation temperature if research data support energy-saving expectations without compromising wine quality.

© The Authors, published by EDP Sciences, 2023

This is an Open Access article distributed under the terms of the Creative Commons Attribution License 4.0, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License 4.0, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

The increased awareness among consumers associations, industries, retailers and other stakeholders about environmental impact of wine production has prompted many wine producers to move toward sustainable grape growing and winemaking practices [1]. Several programs for wine life cycle assessment have recently started to account, among other inputs used along the winemaking phases, equivalent emissions for electricity consumption in the vinification phase, which is in turn influenced by microbial transformations and their management [2-4]. This notwithstanding, the lack of knowledge of energy efficiency opportunities, provides an important obstacle to improving efficiency, even though many operators in wine sector are interested into innovative approaches for energy saving [5].

Heat removal significantly impacts energy request in the winery and is related to the temperature control of wine tanks during the fermentation process and the wine maturation phase. The majority of the electricity used by wineries (about 90%) is consumed by refrigeration systems for process cooling, that is, fermentation control, cold stabilization, and cold storage [6,7]. The fermentation process takes place at a controlled temperature for quality purposes, to which the wine needs to be cooled at the beginning of fermentation and throughout the process; and the fermentation reaction also generates heat that needs to be removed [6]. Overall, fermentation temperature control accounts for as much as 45% of the total energy demand of wineries [8,9].

Regarding alcoholic fermentation, it is known that different fermentation managements lead to wines with different characteristics depending upon yeast strain, fermentation temperature, oxygen and nitrogen management [10-12]. On the contrary, only few works addressed the quantification of required heat dissipation during alcoholic fermentation, coupling innovative thermal protocols with rationally chosen yeast strains [3,5,9]. The quantification of electric energy consumption and estimation of energy conservation showed that increasing the temperature from 15 °C to 19 °C during the fermentation process of 10-hL batches of white base wines yielded an energy saving of ~65% [5], and that approximately 30% less heat had to be dissipated for fermenting Riesling musts under a 16–11–17 °C temperature program, compared with that for fermentation at 14 °C [5,9].

The aim of this work was twin: first, to determine in a wider range of situations the heat dissipated from tanks under different temperature fermentation programs, to evaluate the impact of temperature management combined with specific yeast choice on energy saving during industrial-scale (450 hL) white vinification. Second, to explore the applicability of such protocols, and the extent of the potential effects thereof, through a survey.

2 Materials and methods

2.1 Experimental design and experimental setting

2.1.1 Fermentation setup

Fermentations were performed at industrial scale (450 hL tanks) at Santa Margherita winery, Fossalta di Portogruaro, Italy, during two subsequent vintages (2019 and 2020). In 2019, two fermenters were employed. Glera grapes from Santa Margherita, Fossalta di Portogruaro,VE, Italy, were harvested at ripening. Two vinifications were prepared by crushing the grapes and dividing the resulting liquid (juice) into 2 aliquots after must clarification, performed following the usual winery procedure. In 2020, four fermenters were employed. Pinot Grigio grapes from Santa Margherita, Italy, were harvested at ripening. Four vinifications were prepared by crushing the grapes and dividing the resulting liquid (juice) into 4 aliquots after must clarification, performed following the usual winery procedure. Detailed information about must composition can be retrieved at [13].

2.1.2 Yeast strains

The Saccharomyces cerevisiae yeast strains used in 2019 fermentations (Glera must) were LaClaire CGC62/SP665 (50:50 mix) (Perdomini-IOC, Verona, Italy). The Saccharomyces cerevisiae yeast strain used in 2020 fermentations (Pinot Grigio must) was Mycoferm IT-07 (Ever-Intec, Pramaggiore, Italy). All yeasts were rehydrated from active dry form according to manufacturer instructions, then added to the must at a final concentration of 0.20 g/L.

2.2 Chemical analyses of musts and wines

Chemical must/wine parameters were analysed at the set-up of the trial and at the end of alcoholic fermentation. The analytical methods used were those recommended by the International Organization of Vine and Wine [14]. Volatiles were analysed by gas chromatography—mass spectrometry (GC–MS) after solid-phase extraction (SPME). All the procedures are currently described in [13] and were previously employed in analogous research works [5,15].

2.3 Electric energy consumption evaluation

Comparative tests were carried out during fermentation at different temperatures for the quantification of the energy consumption and the estimation of the energy saving. The studied fermentation plant is located at the “Santa Margherita” winery at Fossalta di Portoguraro (VE) Italy.

In this proceedings, we report comparative evaluations based on the cooling fluid flow time of circulation, calculated as previously described [5]. In detail, all the utilities located in the winery requiring temperature control are served by a centralized refrigeration system. The refrigeration system supplies a closed loop cooling circuit in which circulates cold water and glycol. Depending on the amount of heat to be subtracted at each fermentation tank, a system of valves controlled by thermostats controls in order to keep constant the temperature inside the tank. Tanks at different temperatures were monitored for the quantification of the energy consumption, and time of opening and closure of valves was recorded. The total time of circulation of the fluid throughout alcoholic fermentation was therefore calculated for each tank and compared.

Further details on energy consumption, including absolute calculation of energy demands, can be found by the reader in the recent publication [13], where a methodology to measure energy consumption at different fermentation tanks in the plant was developed and applied, since the monitoring of an industrial-sized plant is more complicated than a laboratory pilot-sized one, therefore.

2.4 Survey preparation and administration to winemakers

A web-based questionnaire [16] was administered to winemakers (one per winery) belonging to Franciacorta DOCG[17] and Prosecco DOC[18] producers, areas located in Lombardia and Veneto regions respectively (Italy). Indeed, even though each method has its specific merits and limitations, direct survey methods continue to be widely used for evaluating willingness to act in the wine sustainability context [19,20].

The data were collected between February and April 2023. The Internet based questionnaire was designed to include information on the winery location and size, the usual fermentation temperature used for white winemaking, the size of average fermenters, the yeasts mainly used, and the availability to modify winery practices for energy savings. Approximately, our sample currently consists of 120 wineries, corresponding to 1.3 million hectoliters production.

3 Results and Discussion

3.1 Temperature impact on yeast performance and final properties of the wines

As expected, the fermentations run at the usual winery-cooling (15 °C in 2019 and 15-17 °C in 2020) ended later compared to the 19°C ones. In all the tanks, a quick beginning of the fermentation was detected, most likely as a consequence of a good implantation of the yeast. A key point for this kind of trials is to properly select yeast strains to be employed based on their attitude towards fermentation performance and aroma production at different temperatures[5,9]. During the whole process, sugar decrease and alcohol increase was constant and reliable in all the fermentations, although with different rates depending on the temperature (data not shown). In 2019, the 19 °C tanks fermented in 5 days, while the 15 °C tanks took 7 days. In 2020, most of the differences in kinetics between the usual winery protocol (17-15 °C) and the innovative one proposed (19 °C) are visible in the time window between 1 and 5 days.

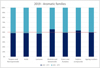

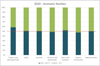

To ensure that the temperature shift from the usual winery protocol (15 °C or 15/17 °C) to 19 °C did not affect the aromatic quality of the wines, analysis of volatile aromas has been performed at the end of alcoholic fermentation on final wines for both vintages. A number of 89 volatile molecules have been analyzed in total. Aromatic compounds are grouped in families and their relative presence is showed, in order to ease the comparison between the two thermal protocols (absolute concentrations of each molecule). Since grape variety and fermenting yeasts were different between the two subsequent vintages, results have been analyzed and presented separately for 2019 and 2020 (Figs. 1 and 2, respectively).

Neither in 2019 (Fig. 1) nor in 2020 (Fig. 2), any of the aromatic families showed a shift higher than 10%. In 2019, alcohols and benzenoids, together with sulphur compounds were slightly decreased moving from 15 °C to 19 °C, and lactones slightly increased. In 2020, the family most affected was Terpens and norisoprenoids (slightly increased).

Most of the aromatic families displayed an opposite trend linked with temperature in the two vintages (e.g. rising in 2019 and lowering in 2020 at higher temperature): this testifies that aroma production did not consistently decrease (or increase) at higher temperature for the tested yeasts.

These results were corroborated by sensory tests performed to guarantee a product with the desired sensory characteristics for the consumers. The method used was a ‘forced choice’ technique employed in a triangular test [5]. The results (data not shown) demonstrated that the panels were not able to distinguish wines fermented at different temperatures, this confirming that fermentation temperature did not significantly impact wine sensorial quality [13]. This is consistent with previous data, also taking into account that the yeast strains involved were different in the two experiments (2019 and 2020), and that different grape varieties and vinification styles were implied (sparkling base wine for Glera in 2019 and finished still wine in 2020). Finally, the “normal” winery thermal protocol compared with the new proposed protocol (19 °C) was different (15 °C in 2019 and 15-17 °C in 2020).

|

Figure 1. Aromatic families concentration ratios at the end of fermentation in 2019. |

|

Figure 2. Aromatic families concentration ratios at the end of fermentation in 2020. |

3.2 Electric energy consumption evaluation

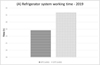

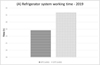

In this extract, comparative evaluations based on the cooling-fluid flow time of circulation are calculated and reported (Figs. 3a and 3b). Tanks at different temperatures were monitored for the evaluation of the energy consumption, and time of opening and closure of valves was recorded.

The refrigerator operated in 2019 for 26.1 hours for Tank V101_19 °C and for 32.0 h for Tank V102_15 °C (Fig. 3a), corresponding to a temperature decrease of 11.2 °C and 18.2 °C respectively. Regarding 2020, for the fermentation temperature of 19 °C, the system works for 38.4 h for Tank V121_19 °C and 34.4 h for Tank V123_19 °C, corresponding in these cases to a temperature decrease of 18.1 °C and 17.3 °C respectively (Fig. 3); for the fermentation temperature of 17-15 °C, the system works for 70.8 h for Tank V122_17-15 °C and 64.7 hour for Tank V124_17-15 °C, corresponding in these cases to a temperature decrease of 23.6 °C and 22.7 °C respectively. The working time of the refrigerator system during fermentation was therefore reduced in both years, achieving a decrease of 46% in 2020.

These data confirm, in a wider scale, previous results: indeed, the reduction of the refrigeration-fluid circulation time was reported up to 80% at smaller industrial volumes [5]. Further experiments in other industrial settings, together with thorough analysis of energy data (already available at [13] for this experiment), will allow to further generalize energy saving expectations other winemaking situations.

|

Figure 3.a Working time of the refrigerator system during fermentation. 2019 trials, innovative protocol (19 °C) vs winery protocol (15 °C). |

|

Figure 3.b Working time of the refrigerator system during fermentation. 2020, average between 2 tanks with STD dev, innovative protocol (19 °C) vs winery protocol (17 °C-15 °C). |

3.3 Survey-based evaluation of fermentation-temperature management and interest in energy savings through winemakers of Northern Italy

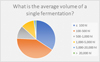

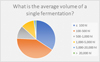

The potential widespread of those effects was investigated through a survey involving several wineries: among others, questions about vinification volumes, usual fermentation temperatures and attitude towards energy-saving innovations were asked to winemakers. Data coming from a first wide sample (n>100) of wineries are currently analyzed. Figure 4 shows the size of the plants belonging to interviewed-producers vinification sites.

Concerning data about vinification protocols and usual fermentation temperatures, our results showed that 85.6% of the wineries work with temperature-controlled tanks, and that fermentation temperature (average) set was 17.5 °C (min. 10; max. 21), whereas cellar temperature (average) was 22 °C (min. 15; max. 28), this suggesting that there is room for improvement.

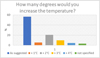

Moreover, about 80% winemakers declared that they are ready to increase the fermentation temperature (if research data support energy-saving expectations without compromising wine quality). Figure 5 shows the willingness to adopt more sustainable fermentation protocols by the interviewed winemakers, this confirming the interest of this research topic in order to provide more and more data to enable winemakers to implement innovative thermal protocols for energy saving purpose.

|

Figure 4. Vinification size (average) declared by interviewed winemakers. |

|

Figure 5. Availability to increase fermentation temperature declared by winemakers. |

4 Conclusions

Our results suggest that wineries can adopt a more sustainable winemaking process with low energy consumption and that this choice may have a relevant impact on white-winemaking energy consumption in the Italian context.

Indeed, data herby presented confirm that properly selected wine yeasts available on the market were able to ferment with good sensorial results at higher temperatures than usual ones employed by wineries. These features have positive effects on energy saving and therefore in reducing the environmental impact of the wine production. Moreover, ~80% of a sample of winemakers representing an overall production of 1.300.000 hL, declared a willingness to increase their usual fermentation temperature if research data support energy-saving expectations without compromising wine quality.

Part of this research was funded by the European Regional Development Fund POR-FESR 2014–2020, in the frame of the “VIT-VIVE” project, earmarked by Regione del Veneto (Italy) with grant number ID:10063685.

The Authors gratefully thank Massimiliano Luison and Lara Malgarin, assistant winemaker at Santa Margherita Winery, for her helpful contribution in following up winery and laboratory trials.

A special acknowledgement is given to “Consorzio per la tutela del Franciacorta” [17] and to “Consorzio di tutela della Denominazione di Origine Controllata Prosecco” [18] for their collaboration in administrating the online survey to associated wineries.

References

- C. Santini, A. Cavicchi, and L. Casini, Agric. Food Econ. 1, 9 (2013) [CrossRef] [Google Scholar]

- R. Merli, M. Preziosi, and A. Acampora, J. Clean. Prod. 172, 3791 (2018) [CrossRef] [Google Scholar]

- T. Nardi, Microorganisms 8, 507 (2020) [CrossRef] [PubMed] [Google Scholar]

- G. Trioli, A. Sacchi, C. Corbo, and M. Trevisan, Internet J Viticult Enol 7, 2 (2015) [Google Scholar]

- V. Giovenzana, R. Beghi, P. Vagnoli, F. Iacono, R. Guidetti, and T. Nardi, Am. J. Enol. Vitic. 67, 308 (2016) [CrossRef] [Google Scholar]

- C. Galitsky, E. Worrell, A. Radspieler, P. Healy, and S. Zechiel (2005) [Google Scholar]

- M. Malvoni, P. M. Congedo, and D. Laforgia, Energy Procedia 126, 227 (2017) [CrossRef] [Google Scholar]

- R. Celorrio, J. Blanco, E. Martínez, E. Jiménez, and J. C. Saenz-Díez, Am. J. Enol. Vitic. 67, 94 (2016) [CrossRef] [Google Scholar]

- M. Schwinn, D. Durner, M. Wacker, A. Delgado, and U. Fischer, Aust. J. Grape Wine Res. 25, 173 (2019) [CrossRef] [Google Scholar]

- E.J. Bartowsky and P.A. Henschke, Aust. Grapegrow. Winemak. Aust. (1995) [Google Scholar]

- G.H. Fleet, Int. J. Food Microbiol. 86, 11 (2003) [CrossRef] [Google Scholar]

- M. Ugliano and P.A. Henschke, in Wine Chem. Biochem. (Springer, 2009), pp. 313-392 [CrossRef] [Google Scholar]

- V. Giovenzana, R. Beghi, R. Guidetti, M. Luison, and T. Nardi, J. Agric. Eng. (2023) [Google Scholar]

- OIV (2018) [Google Scholar]

- M. Azzolini, B. Fedrizzi, E. Tosi, F. Finato, P. Vagnoli, C. Scrinzi, and G. Zapparoli, Eur. Food Res. Technol. 235, 303 (2012) [CrossRef] [Google Scholar]

- I. Vigentini and T. Nardi, Risparm. Energ. Vinif. - Indagine Conoscitiva (2023) [Google Scholar]

- Consorzio Tutela Franciacorta Str. Franciacorta (2023) [Google Scholar]

- Consorzio Tutela Prosecco DOC (2023) [Google Scholar]

- R. Capitello and L. Sirieix, Economies 7, 33 (2019) [CrossRef] [Google Scholar]

- E. Pomarici and R. Vecchio, Wine Econ. Policy 8, 1 (2019) [CrossRef] [Google Scholar]

All Figures

|

Figure 1. Aromatic families concentration ratios at the end of fermentation in 2019. |

| In the text | |

|

Figure 2. Aromatic families concentration ratios at the end of fermentation in 2020. |

| In the text | |

|

Figure 3.a Working time of the refrigerator system during fermentation. 2019 trials, innovative protocol (19 °C) vs winery protocol (15 °C). |

| In the text | |

|

Figure 3.b Working time of the refrigerator system during fermentation. 2020, average between 2 tanks with STD dev, innovative protocol (19 °C) vs winery protocol (17 °C-15 °C). |

| In the text | |

|

Figure 4. Vinification size (average) declared by interviewed winemakers. |

| In the text | |

|

Figure 5. Availability to increase fermentation temperature declared by winemakers. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.