| Issue |

BIO Web Conf.

Volume 68, 2023

44th World Congress of Vine and Wine

|

|

|---|---|---|

| Article Number | 02025 | |

| Number of page(s) | 6 | |

| Section | Oenology | |

| DOI | https://doi.org/10.1051/bioconf/20236802025 | |

| Published online | 06 December 2023 | |

Application of ultra-high pressure homogenization (UHPH) at different stages of wine production

1 INCAVI-IRTA. Catalan Institute of Vine and Wine - Institute of Agrifood Research and Technology. Plaça Àgora, 2. 08720 Vilafranca del Penedès, Barcelona, Spain

2 Servei Planta Pilot de Tecnologia dels Aliments and 3Centre d’Innovació, Recerca i Transferència en Tecnologia dels Aliments (CIRTTA), CERTA-TECNIO, MALTA-Consolider, Departament de Ciència Animal i dels Aliments, Facultat de Veterinària, Universitat Autònoma de Barcelona, 08193 Bellaterra, Barcelona, Spain

Ultra-High Pressure Homogenization (UHPH) is an emerging, efficient and fast technology that can be applied at different stages in winemaking in order to reduce or avoid the use of sulphites or other antimicrobial and antioxidant treatments. During 2022 vintage, four batches of must of three different white cultivars (Vitis vinifera L.) were processed by UHPH at 300 MPa with an inlet temperature (Ti) of 4 ºC and their effectiveness was compared with control batches (without SO2 addition) and musts that were sulphited with 60 mg/L of total SO2. A complete inactivation of yeasts and bacteria was achieved when grape juices were processed by UHPH, reaching up to 7 log of reduction in yeasts, 4.6 log for acetic acid bacteria and 4.3 log for lactic acid bacteria. All UHPH musts remained stable from a microbiological point of view for more than 8 months stored at 4 ºC in aseptic containers. Results showed that when antioxidant activity, colour intensity and total phenol index were measured, UHPH can be considered a protective technique, with a similar action to that of adding SO2. Furthermore, PPO enzymatic activity was completely inactivated in UHPH and sulphited musts. When a red wine contaminated by Brettanomyces was treated by UHPH at 300 MPa and Ti = 17 ºC, a 6.6 log reduction was obtained for this spoilage microorganism and no increase of volatile phenols were detected after 2 months.

© The Authors, published by EDP Sciences, 2023

This is an Open Access article distributed under the terms of the Creative Commons Attribution License 4.0, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License 4.0, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

In the last decades, the wine sector has shown an increasing interest in the application of innovative technologies, particularly in certain non-thermal physical methods able to improve process efficiency and reduce the use of chemical inputs. Specifically, in winemaking, the reduction and/or elimination of sulphite dosages in the final product is one of the main challenges that the sector is facing, in order to obtain wines with preservative-free labels and with the maintenance of its maximum quality during its commercial shelf-life, both at a microbiological, physical-chemical and sensory level. Among these new technologies, high pressures are currently claimed to be one of the most promising non-thermal techniques that can be applied to improve fluid foods quality and safety. Recently, the International Organization of Vine and Wine (OIV) has approved and included UHPH (Ultra High Pressure Homogenization) among the recommended practices in the international oenological code [1].

The UHPH exerts a homogenization process at high pressures and is applied directly to the liquid to be treated by means of a continuous system. During the process, the liquid is pumped into the equipment at a pressure equal to or greater than 200 MPa and then it is immediately depressurized through a valve made of high-resistance material. Passing through the valve causes a series of mechanical forces, mainly impact and shear, but also cavitation and friction, which produce an antimicrobial effect, destroying microorganisms such as yeasts and bacteria, and an anti-enzymatic effect due to protein denaturation. In addition, the UHPH technology can be considered protective at the sensory level since the energy generated in the process is not enough to alter structures such as pigments, aromatic compounds or substances that give flavour [2,3]. Several potential uses in winemaking of high pressure homogenization (HPH), a very similar technology to UHPH, have been also described [4].

This study is focused on checking the validity of the use of the UHPH technique in the control of wild microorganisms in white grape musts from different varieties and to evaluate their repercussion in oenological and colour parameters, as well as antioxidant aspects.

Moreover, the study of new approaches to control the presence of Brettanomyces spp. in winemaking have increased due to the greater presence of this spoilage microorganism in the winery environment and bottled wines. The production of volatile phenol compounds, the high stress resistance of this specie and the peculiar metabolic features make it necessary to found efficient technologies to inhibit its growth. This work also aims to evaluate the effectiveness of UHPH in the inactivation of a spoilage yeast such as Brettanomyces bruxellensis and to control the formation of volatile phenols.

2 Materials and methods

2.1 Musts and wine samples preparation

Grapes from three Vitis vinífera L. white cultivars: Xarel·lo (Xar) (two batches: Xar 1 and Xar 2), Muscat of Alexandria (M) and white Grenache (Gw) were pressed in a pneumatic press and the running must was settled at 4 ºC using pectolytic enzymes for 24 hours. Clean musts were separated in 3 fractions preserved under inert CO2 atmosphere and: (i) one kept as a control without adding SO2 nor UHPH treatment, (ii) one without SO2 and processed by UHPH and (iii) one with addition of 60 mg/L of total SO2. UHPH treatment was performed using a continuous operating mode device (Ypsicon Advanced Technologies, Barcelona, Spain) built under patent by Universitat Autònoma de Barcelona (EP2409583B1) (Fig. 1). The working flow rate was 60 L/h at 300 ± 2 MPa, with an inlet temperature (Ti) of 4 ºC, an in-valve temperature of 95 ºC ± 2 ºC for less than 0.2 s, and an outlet temperature of 14 ºC. The UHPH-treated must was cooled down after the valve in a heat exchanger through which water was circulating at 4 ºC, aseptically packed in bag-in-box of 3 L of capacity and stored at 4 ºC. The total volume of must processed by UHPH was 30 L. Different microbiological and oenological parameters were analysed for each must at T = 0, 1, 2, 4, 6 and 8 months after being packaged.

For Brettanomyces inactivation experience, an aged red wine from Appellation of Origin Terra Alta (Catalonia, Spain) naturally polluted with Brett were used. Wine was divided in two batches: (i) control without any treatment and (ii) treated by UHPH. This last was processed with the same UHPH equipment described above, at 300 ± 2 MPa, with a Ti = 17 ºC, an in-valve temperature of 94 ºC ± 2 ºC for less than 0.2 s, and an outlet temperature of 19 ºC. Once treated, control and UHPH wines were bottled and stored at 14 ºC. Brett population, acetic acid and volatile phenols were analysed at time 0 and 2 months.

|

Figure 1 UHPH equipment used in this study for processing must and wine samples. |

2.2 Microbial counts

Microbiological analyses were carried out on the control, sulphited and UHPH-treated musts and for red wine spoiled with Brettanomyces. One milliliter of serial decimal dilutions in Ringer buffer (Scharlau, Barcelona, Spain) were pour-plated in selective media for total yeast- counts, lactic acid bacteria, acetic acid bacteria or Brettanomyces. In some cases, 1 mL up to 100 mL of sample volume was concentrated in 0.45 µm (yeasts) or 0.22 µm (bacteria) membrane sterile filters (Filter-Lab, Barcelona, Spain) and incubated onto the surface of the plates of the selective media. The media were for yeast counts: Sabouraud chloramphenicol agar (Scharlau, Barcelona, Spain) incubated aerobically for 2 days at 28 ºC; for lactic acid bacteria counts: MRS agar (Scharlau, Barcelona, Spain) supplemented with nystatin (50 mg/L) after sterilization and incubated for 10 days at 28 ºC in a jar under microaerophilic conditions; for acetic acid bacteria counts: GYC Agar (Glucose 5%, Yeast Extract 1%, Calcium carbonate 0.5%, Agar-agar 2%) supplemented with nystatin (50 mg/L) after sterilization and incubated for 5 days at 28 ºC in aerobic conditions; and for Brettanomyces counts: KitBrett (Vivelys, France) incubated at 28 ºC for 7 days.

2.3 Oenological parameters

The following parameters were evaluated in all musts batches just after UHPH treatment: ºBrix, (% v/v), pH, total acidity (g/L in tartaric acid), free SO2 (mg/L) and total SO2 (mg/L) were determined in accordance with the Compendium of International Methods of Wine and Must Analysis-OIV [5]. Volatile acidity (g/L in acetic acid), L-malic acid (g/L), lactic acid (g/L) and yeast assimilable nitrogen (YAN) (mg/L) were analysed in a multi-parametric analyser Miura (TDI Tecnología Difusión Ibérica, S.L., Barcelona, Spain) by enzymatic methods. Turbidity was measured in a turbidimeter Hitachi.

For volatile phenols (4-ethylphenol and 4-ethylguaiacol) analysis, a gas chromatograph 7890A (Agilent Technologies, Barcelona, Spain) equipped with a mass spectrometer 5975C was used. For sample preparation, 5 mL of wine were mixed with a mixture of diethyl ether and hexane (3:6, 2 mL). A portion of the organic layer was then transferred to a vial ready for instrumental analysis. A constant flow of 1 mL/min of He was used as carrier gas. The injected volume was 2 µL of the extract by means of a splitless injector 7683B (Agilent Technologies) coupled to the chromatograph. The injector temperature was maintained at 200 ºC. The ionization was carried out by electronic impact (70 eV) and the detector temperatures were 150 °C (quadrupole), 230 °C (ionization source) and 250 °C (transfer line). Compounds were quantified in selective ion monitoring (SIM) mode.

2.4 Colour parameters and total phenol index (TPI)

To eliminate the interfering substances, previously to determination, the musts (2 mL) were passed through a Seppak C18 cartridge previously activated (2 mL methanol and washed with distilled water). The polyphenol substances were eluted with 2 mL of methanol and 5 mL of water. Then, Total Phenol Index (TPI), was estimated as A280, hydroxycinnamic compounds (Hc) were considered to be A320 and brown pigments as A420. Colour intensity (CI) was calculated as the sum of A420, A520 and A620 [6]. Absorbance measurements were made in a Beckman spectrophotometer (DU 600 model) on 10 mm path length.

2.5 Antioxidant activity and polyphenol oxidase (PPO) inactivation

Two different tests were used to assess the antioxidant capacity of the musts: (i) the 2,2′-azino-bis-3-ethylbenzothiazoline-6-sulfonic acid (ABTS) assay determined as [7] and expressed as Trolox equivalent antioxidant capacity (TEAC μmol/100 mL) and (ii) the potential antioxidant index (PAT) [8] based on the FRAP method and expressed as mM of ascorbic acid (Vitamin C).

The polyphenol oxidase (PPO) activity was monitored with the methodology described by [9] with some modifications. Basically, the absorbance A420 developed by the reaction between the enzyme and pyrocatechol was measured during 200 s. One unit of PPO activity is defined as the increase of 0.001 absorbance units per minute, calculated as the increase in absorbance/min in the linear part of the curve.

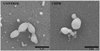

2.6 Scanning electronic microscopy (SEM)

Red wine samples (2.5-10 mL) with Brettanomyces (control or treated by UHPH) were filtered by polycarbonate membrane (Merck Life Science, Darmstadt, Germany) of 25 mm diameter with 0.2 µm pore size. Then, they were fixed with 2.5% glutaraldehyde in PB 0.1M overnight at 4 ºC, post-fixed with 1% osmium tetroxide with 0.8% potassium ferrocyanide overnight and dehydrated in increasing concentrations of ethanol (50, 70, 90, 96, 100%). Finally, samples were chemically dried with hexamethyldisilazane and sputtered-coated with a thin layer of PdAu for 4 min at 20 mA. Images were acquired with a SEM Hitachi S570 (Hitachi Ltd., Tokyo, Japan) at 20 kV.

2.7 Data analysis

Means and standard deviations were calculated, and differences examined using ANOVA, selecting p ≤0.05 for significance of comparisons. All calculations were performed with XLSTAT-Pro 201610 (Addinsoft 2009, París, France) statistical software package.

3 Results and Discussion

3.1 Oenological parameters in grape musts

Musts processed by UHPH are affected by strong impact and shear forces producing nanofragmentation of colloidal particles in the matrix and affecting their structure [2]. This causes an increase of turbidity (NTU) in all UHPH samples as is shown in Table 1. Bañuelos et al. [3] already detected a higher content of total suspended solids in UHPH-treated musts of Muscat of Alexandria due to the intense fragmentation of the grape cell wall produced after depressurization in the valve of UHPH equipment. Also, colloidal turbidity in UHPH wines were higher at the end of alcoholic fermentation, compared to control wines. However, after fining with bentonite or bentonite/gelatine no differences in the brightness were observed in UHPH or control wines. These results have also been repeated in this study when must of Xar 2 batch has been fermented and the resulting wines after clarification have been analysed (data not shown).

In this study, no differences were found in Yeast Assimilable Nitrogen (YAN) concentration between treatments (C, UHPH or SO2) in any of the four musts studied, contrary to that was shown in [3], where higher contents (25% more) of YAN was found in UHPH processed musts.

Slightly higher pH was measured in UHPH-treated must in Xar 1 and Gw musts with respect to the control and SO2 batches, probably due to the higher extraction of salts and cations by fragmentation of solid colloids as pointed out in [2]. No other significant differences were observed in the rest of the parameters analysed.

Main oenological parameters of the four must batches: C (control without SO2), UHPH (without SO2 and just after UHPH processing) and SO2 (with addition of 6 g/hL of total SO2).

3.2 Microbial counts and inactivation by UHPH

Yeast populations in controls (C) of the four batches ranged from 3 × 105 CFU/mL in white Grenache must to 1.1 × 106 CFU/mL in Muscat of Alexandria must (Fig. 2). The presence of SO2 at high doses (6 g/hL) reduced the load of yeasts between 0.5 log in Muscat and 2.5 log in the case of Xarel·lo 2 must. A complete inactivation of yeasts was achieved when musts were processed by UHPH: no yeasts were found in at least 10 mL of volume analysed, thus reaching up to 6 log of reduction. Similar results were obtained by [3,9].

After UHPH processing, all culturable bacterial cells analysed (acetic and lactic acid bacteria) were eliminated in musts samples, achieving reductions up to 4.6 log for acetic acid bacteria and 4.3 log for lactic acid bacteria. The addition of 6 g/hL of SO2 to the musts did not reach a total inactivation of the acetic bacteria neither the lactic acid bacteria, since populations of more than 3 logs, in both cases, were detected depending on the batch of musts analysed (Fig. 2).

Untreated control musts and sulphited musts started fermenting by the indigenous yeast populations after 1-3 days (data not shown). All UHPH musts have remained stable from a microbiological point of view (no yeasts, no acetic or lactic acid bacteria) for more than 8 months stored at 4 ºC in aseptic containers. This fact proves that the shear efforts, impact, cavitation and friction that UHPH exerts in the valve when 300 MPa of pressure are applied are enough to fully eliminate grape microorganisms, even in musts with high microbial populations. Bañuelos et al [3] demonstrated that UHPH musts kept in closed vials remained unfermented during at least four months at 18 ºC.

The microbiological stability of musts achieved by UHPH treatment for more than 8 months could make it possible to seasonally adjust its use, beyond the harvest period.

|

Figure 2 Total yeasts, acetic bacteria and lactic acid bacteria counts in control musts (C), processed by UHPH (UHPH) and sulphited with 6 g/hL of total SO2 (SO2) (T = 0 days). |

3.3 Colour parameters and total phenol content

No significant differences were observed in total phenol index (TPI) among treatments in three of the musts. Xar 1, Xar 2 and Gw showed similar initial contents of polyphenols. Only in Muscat of Alexandria, significant differences were detected between control (C) and SO2 musts. However, in all cases, controls always had the highest value (Table 2).

In general, higher colour intensity (CI) was measured in controls (non-treated) musts probably due to browning oxidative reactions related to the lack of sulphites. This fact is in accordance with the values of the A420: control showed higher and significant differences with respect to UHPH and SO2 treatments. Although in Xar 1 and M musts the lowest values in A420 were reached in the samples processed with sulphites, no significant differences (p>0.05) were found between UHPH and SO2 in none of the musts (Table 2). Therefore, UHPH can be considered a protective technique in both CI and IPT, with an action similar to that of adding SO2. Similar results were obtained in [2,3,9].

Regarding hydroxycinnamic acids (A320), no general trend was detected but there seemed to be a varietal effect.

Total phenol index (TPI), hydroxycinnamic acids (A320), brown pigments (A420) and colour intensity (CI) of the four musts batches: control (C), UHPH and sulphited (SO2). Values are means of triplicates. The same parameter with the same letter are not significantly different (p > 0.05).

3.4 Antioxidant capacity and PPO enzymatic activity of white musts

Antioxidant activity allows to know the resistance to oxidation of musts and determine which one will better withstand the passage of time. It was analysed by two methods and both gave very similar results (Table 3). In general, SO2 treatment registered the highest values, followed by UHPH and control samples, although in some cases (Muscat and white Grenache samples) slight differences were found between sulphited and UHPH musts. It is well known the antioxidant capacity of high doses of SO2, but these results have shown that UHPH treatment at 300 MPa can preserve the phenolic fraction of musts from oxidation, being more stable without the need to use SO2. Loira et al [9] and Bañuelos et al [3] found the same behaviour when analysing musts of two white varieties processed by UHPH.

Grape juices with active PPO enzymes are more prone to suffer oxidative reactions during winemaking and, consequently, decreasing the quality of the final wine [10]. As it is shown in Table 3, PPO activity was completely inactivated in UHPH and sulphited musts, while different degrees of activity were detected in the control batches depending on each variety. Previous works [2,3,9] also reported the inactivation of PPO enzymes by UHPH processing.

The strong inactivation of PPO by UHPH at 300 MPa opens clear opportunities for the reduction or suppression of sulphites in winemaking, because of the simultaneous antioxidant and antimicrobial effects of this emerging technology.

Antioxidant activity of musts control (C), processed by UHPH (UHPH) and sulphited with 6 g/hL of SO2 (SO2) using two different tests: PAT and DPPH methods. Polyphenol oxidase (PPO) activity measured as the absorbance at A420 resulting from the reaction between the enzyme and pyrocatechol over time.

3.5 UHPH effect in Brettanomyces and volatile phenols evolution

Spoilage microorganisms such as Brettanomyces spp. that can be present in wines, above all aged red wines, can be easily destroyed by UHPH processing [11]. The present work shows the first results about the evolution over time in the bottle of Brett population, volatile phenols and acetic acid of a red wine naturally contaminated with this yeast and processed by UHPH at 300 MPa in comparison with the control wine without any treatment.

Samples were analysed just after UHPH treatment and two months later. Brett load in control wine at the beginning of the study was 1,36 × 104 CFU/mL and an increase of 0.5 log was detected 60 days later (Table 4). Instead, UHPH treatment inactivated all Brett population, and no growth was found after two months when 100 mL of wine sample were filtered and analysed. Thus, a 4.1 log reduction of Brett was achieved by UHPH processing.

Regarding volatile phenols, and taking into account the uncertainty of the analysis method, an increase in the concentration of 4-ethylphenol was recorded after 2 months of remaining the control wine (not treated) in the bottle. No evolution was found in phenol levels in the UHPH wine. Acetic acid values were always higher in the control wine, and a slightly decrease in its level was observed in UHPH wine after two months (Table 4).

The work of Pinto et al [12] cited different physical methods to control Brettanomyces spp. during the winemaking and UHPH as a promising future emerging technology. In the study of Van Wyk et al [13], more than 5 log Brettanomyces bruxellensis reduction was achieved when High Hydrostatic Pressure (HHP) treatment was applied in red wines and was the only treatment which prevented the formation of the spoilage volatile phenols, 4-ethylphenol and 4-ethylguayacol, until one year of storage after treatment.

In order to verify the impact of UHPH treatment on Brettanomyces cells, the samples were observed by SEM. SEM observations showed in control wine an elongated and whole cells forming bicellular structures (non-separation of daughter cells) while in UHPH the cell structure appeared damaged, having lost its original shape and with cells with broken walls (Fig. 3).

Brettanomyces counts (CFU/mL), volatile phenols (4-ethylphenol and 4-ethylguayacol) (µg/L) and values of acetic acid (g/L) in the red wine naturally spoiled with Brett (Control) and UHPH treated (UHPH) at time 0 days (T=0) and after 2 months of being bottled.

|

Figure 3 Scanning electron microscopy of red wine samples contaminated by Brettanomyces bruxellensis. Control (no UHPH processing) and UHPH (processed by UHPH). |

4 Conclusions

The antimicrobial, but also antioxidative effect of UHPH in the four musts analysed in this work opens a clear potential for using this technique to obtain musts and produce wines with low levels of SO2 or without it. In addition, this treatment allows extending the shelf-life of the grape juice to deseasonalize its use.

This study has also demonstrated the efficacy of the UHPH treatment to inactivate the growth of spoilage microorganisms such as Brettanomyces bruxellensis, as well as the production of undesirable microbial metabolites such as volatile phenols to minimize sensory changes in wines.

This research has been funded by the project FRUHPH “Application of Ultra High Pressure Homogenization in fruit juices and wines to improve quality and preservation without additives”. Grup Operatiu from Generalitat de Catalunya (PDR 2014-2022).

The authors would like to thank the wineries from DOP Penedès and DOP Tarragona (Catalonia, Spain) that provided the musts and red wine for this study. And E. Valdés and D. Moreno from CICYTEX-INTAEX for their advices on the interpretation of some of the results.

References

- OIV. RESOLUTION OIV-OENO 594B (2020). https://www.oiv.int/public/medias/7587/oiv-oeno-594b-2020-en.pdf [Google Scholar]

- C. Vaquero, C. Escott, I. Loira, B. Guamis, J.M. del Fresno, J.M. Quevedo, R. Gervilla, S. de Lamo, R. Ferrer-Gallego, C. González, M.A. Bañuelos, J.A. Suárez-Lepe, A. Morata, Food Bioprocess Technol. 15, 620 (2022) https://doi.org/10.1007/s11947-022-02766-8 [CrossRef] [Google Scholar]

- M.A. Bañuelos, I. Loira, B. Guamis, C. Escott, J.M. Del Fresno, I. Codina-Torrella, J.M. Quevedo, R. Gervilla, J.M. Rodríguez Chavarría, S. de Lamo, R. Ferrer-Gallego, R. Álvarez, C. González, J.A. Suárez-Lepe, A. Morata. Food Chem. 332, 127417 (2020) https://doi.org/10.1016/j.foodchem.2020.127417 [CrossRef] [Google Scholar]

- P. Comuzzo, S. Calligaris. Beverages 5, 56 (2019) https://doi.org/10.3390/beverages5030056 [CrossRef] [Google Scholar]

- OIV. Compendium of international methods of wine and must analysis. 1 and 2, (2023) https://www.oiv.int/sites/default/files/publication/202305/Compendium%20MA%20complet_EN.pdf [Google Scholar]

- P. Iland, A. Ewart, A. Markides, J. Sitters, N. Bruer, Ed. Patrick Iland Wine Promotions, Campbelltown, Australia, (2000), pp. 88-91 [Google Scholar]

- R. Re, N. Pellegrini, A. Proteggente, A. Pannala, M. Yang, C. Rice-Evans, Free Radic. Biol. Med. 26, 1231–1237 (1999) https://doi.org/10.1016/S0891-5849(98)00315-3 [CrossRef] [Google Scholar]

- A. El-Haitum, S.M. Amrani, N. Gougoulias, Z. Daoudi, L. Masheva, N. Mashev. Oxid. Commun. 31(3), 527–536 (2008) [Google Scholar]

- I. Loira, A. Morata, M.A. Bañuelos, A. Puig-Pujol, B. Guamis, C. González, J.A. Suárez-Lepe. Innov. Food. Sci. Emerg. Technol. 50, 50 (2018) https://doi.org/10.1016/j.ifset.2018.10.005 [CrossRef] [Google Scholar]

- M. Hendrickx, L. Ludikhuyze, I. Van den Broeck, C. Weemaes. Trends Food Sci. Technol. 9(5), 197–203 (1998) https://doi.org/10.1016/S0924-2244(98)00039-9. [CrossRef] [Google Scholar]

- A. Morata, B. Guamis. Front. Nutr. 7, 598286 (2020) https://doi.org/10.3389/fnut.2020.598286 [CrossRef] [Google Scholar]

- L. Pinto, F. Baruzzi, L. Cocolin, M. Malfeito-Ferreira, M. Trends Food Sci. Technol. 99, 88–100 (2020) https://doi.org/10.1016/j.tifs.2020.02.013 [Google Scholar]

- S. Van Wyk, M.M. Farid, F.V. Silva. Innov. Food Sci. Emerg. Technol. 48, 204–211 (2018) https://doi.org/10.1016/j.ifset.2018.06.016 [CrossRef] [Google Scholar]

All Tables

Main oenological parameters of the four must batches: C (control without SO2), UHPH (without SO2 and just after UHPH processing) and SO2 (with addition of 6 g/hL of total SO2).

Total phenol index (TPI), hydroxycinnamic acids (A320), brown pigments (A420) and colour intensity (CI) of the four musts batches: control (C), UHPH and sulphited (SO2). Values are means of triplicates. The same parameter with the same letter are not significantly different (p > 0.05).

Antioxidant activity of musts control (C), processed by UHPH (UHPH) and sulphited with 6 g/hL of SO2 (SO2) using two different tests: PAT and DPPH methods. Polyphenol oxidase (PPO) activity measured as the absorbance at A420 resulting from the reaction between the enzyme and pyrocatechol over time.

Brettanomyces counts (CFU/mL), volatile phenols (4-ethylphenol and 4-ethylguayacol) (µg/L) and values of acetic acid (g/L) in the red wine naturally spoiled with Brett (Control) and UHPH treated (UHPH) at time 0 days (T=0) and after 2 months of being bottled.

All Figures

|

Figure 1 UHPH equipment used in this study for processing must and wine samples. |

| In the text | |

|

Figure 2 Total yeasts, acetic bacteria and lactic acid bacteria counts in control musts (C), processed by UHPH (UHPH) and sulphited with 6 g/hL of total SO2 (SO2) (T = 0 days). |

| In the text | |

|

Figure 3 Scanning electron microscopy of red wine samples contaminated by Brettanomyces bruxellensis. Control (no UHPH processing) and UHPH (processed by UHPH). |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.